Manufacturing Services

SMT

Automation

Production Lines

Quality Control & Compliance

Plastic & Tooling

SMT

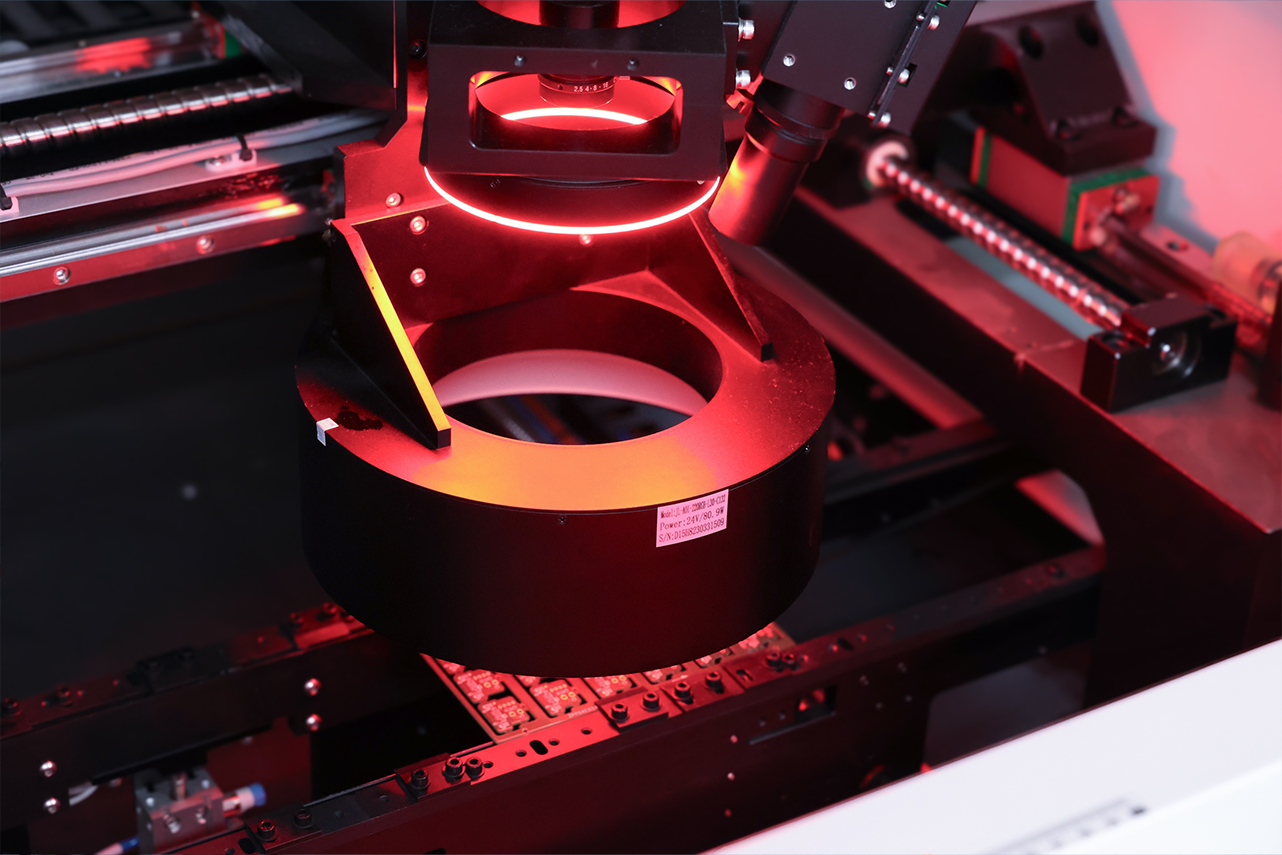

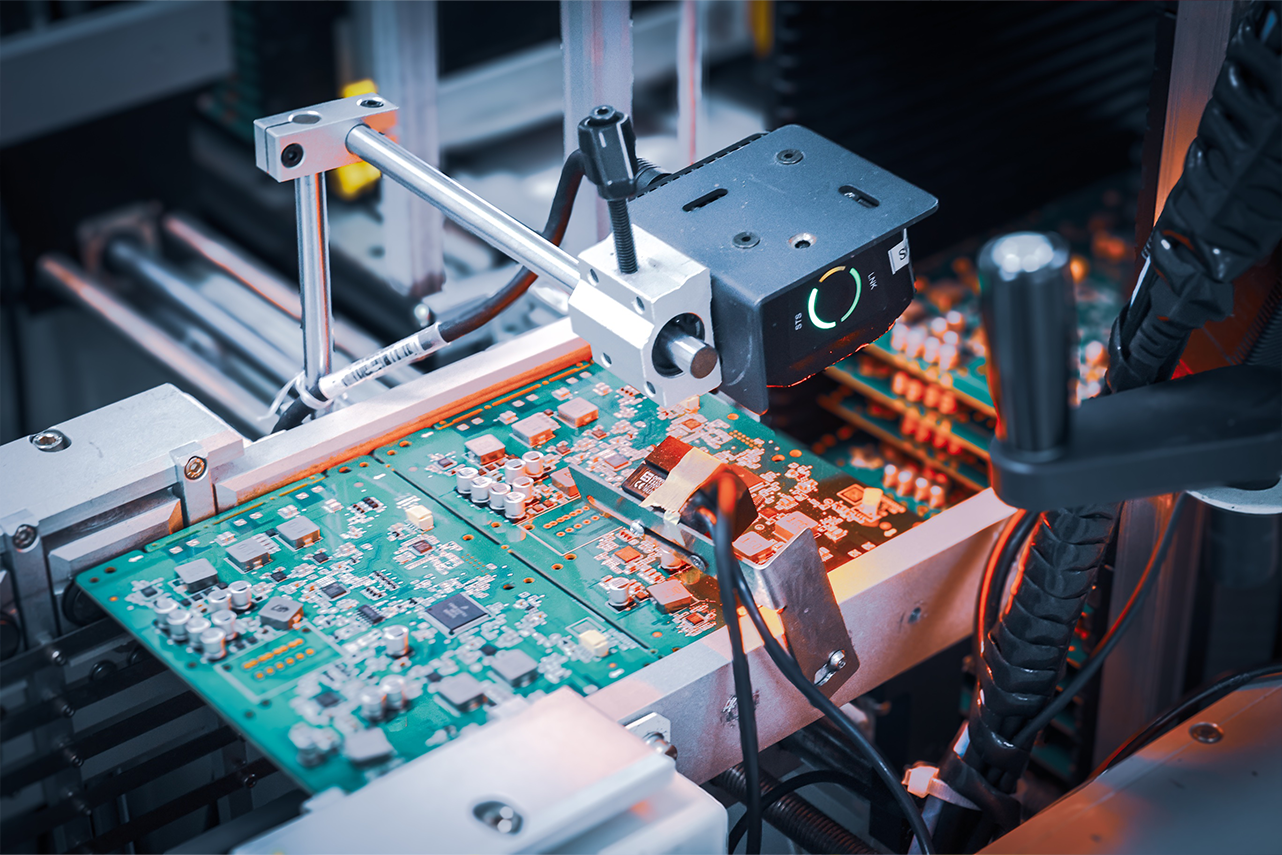

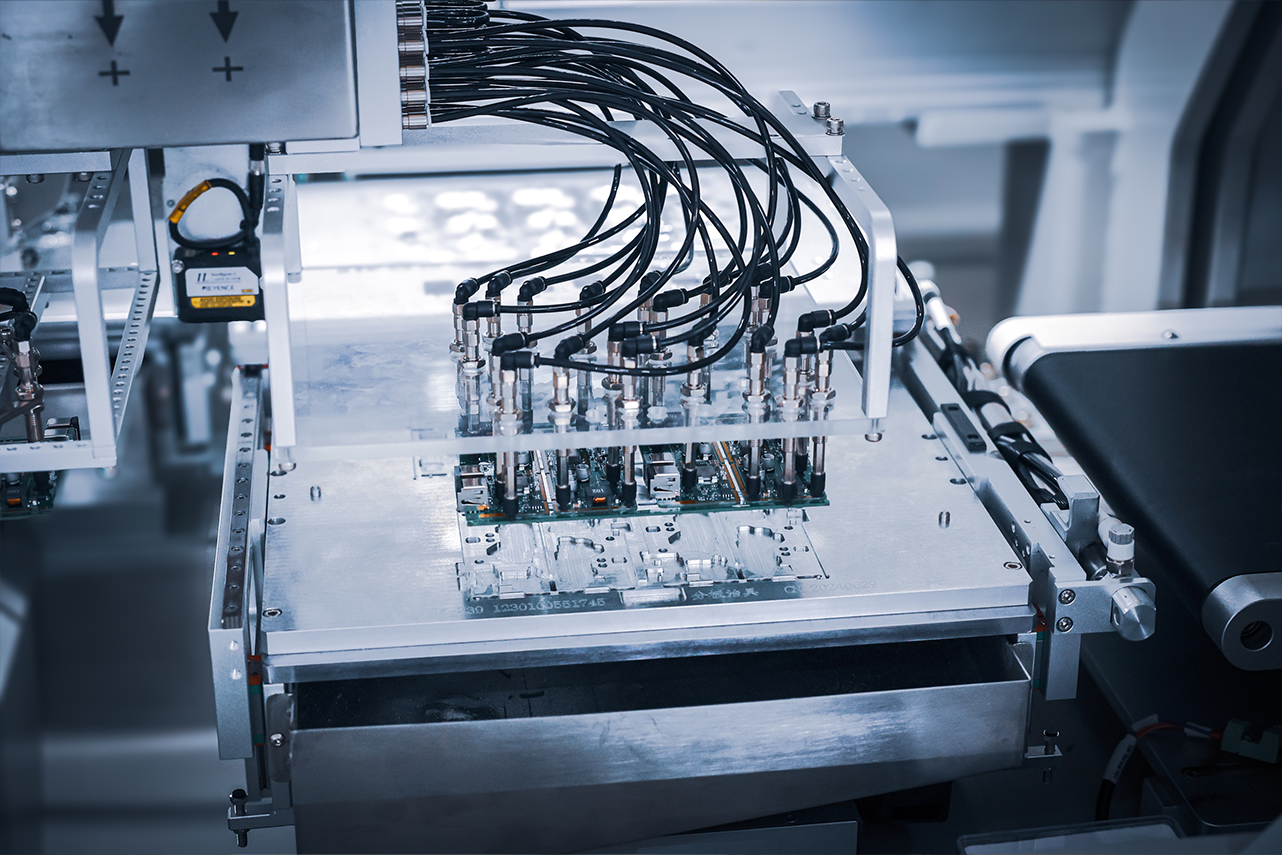

Our SMT services provide high-precision assembly for a wide range of electronic components. With advanced machinery and automated inspection systems, we ensure consistent quality and efficiency throughout production. Our SMT lines are optimized for accuracy and speed, delivering reliable solutions for even the most complex designs.

6 Fully Automated

SMT Lines

6 Million

Components / Day

99.8% First Pass

Yield

< 200 PPM

Defective Rate

In-Line

AOI and SPI

Inspection

X-Ray Inspection

and Analysis

Full Components

Traceability

Laser etching 2D

Barcode on PCB

Rigorous Quality Assurance

Ersa Selective Soldering systems deliver precision and flexibility , particularly in automotive PCBAs manufacturing. We employ in-line SPI and AOI for continuous quality checks, along with X-ray inspection for detailed analysis of solder joints and hidden components, ensuring reliability in every product.

Explore the future of electronics with us

Contact Us

Country Mate Technology Limited

Flat/RM E, 5/F, Hing Yip Centre, 31 Hing Yip Street, Kwun Tong, Kowloon, Hong Kong

mkt_info@countrymate.com

Tel : (+852) 2797 0605

Fax : (+852) 2341 8363

Concord Intelligent Technology (Huizhou) Ltd.

No.3 Jiayu Road, Dongxing Sub-district,

Dongjiang Science and Technology Park,

Zhongkai Hi-tech Industrial Development Zone, Huizhou,

Guangdong, P.R. China

Tel : (+86) 752-2309 002

Fax : (+86) 752-2309 047

Concord Mate (Vietnam) Co., Ltd.

2nd Floor, Factory 2, Lot F1-2-3, Thang Long Vinh Phuc Industrial Park,

Binh Nguyen Commune, Phu Tho Province, Vietnam

Tel : (+84) 21 1389 0888

SOLUTIONS

COMPANY

Copyright © 2025 Country Mate Technology, All Rights Reserved.